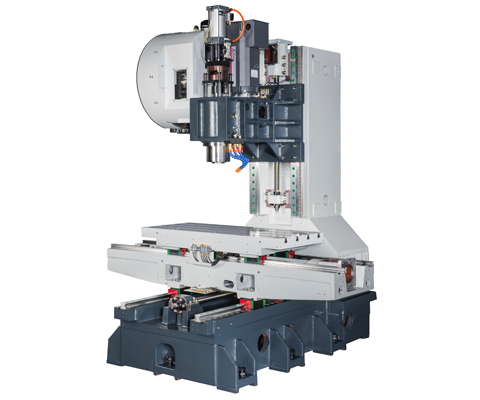

QMC-1050

The Maxmill QMC-1050 is a well-balanced, high-speed, high production CNC machine ideally suited for mold and metal cutting industries.

This machine is built with power and precision for fast cycle times, and features the user-friendly Mitsubishi M80 High-Performance CNC controller.

| TRAVEL | X x Y x Z axis | 41.3 x 21.6 x 22.0 mm |

| Spindle nose to table | 4.7~680 mm | |

| Spindle center to solid column surface | 600 mm | |

| TABLE | Working area | 1,150 x 26.7 mm |

| Max. loading | 1500 lbs. | |

| T-Slots (No. x Width x Pitch) | 4 x .700 x .5 mm | |

| SPINDLE | Tool shank | CAT-40 Big Plus |

| Speed | 15,000 rpm | |

| Transmission | Direct Drive | |

| Bearing lubrication | Grease | |

| Cooling system | Oil cooled | |

| Spindle motor max.rating (FANUC) | 15HP / 20HP | |

| Axis motor max. rating (FANUC) | 3.2 / 3.2 / 3.2 HP (STD) 4.0 / 4.0 / 5.36 HP (OPT) |

|

| FEED RATES | Rapids on X & Y & Z axis(linear way) | 1417 / 1417 / 1417 m/min |

| Max. cutting federate | 394 m/min | |

| TOOL MAGAZINE | Tool storage capacity | 30 arm |

| Type of tool (optional) | CAT- 40 | |

| Max. tool diameter | 100 mm / 76 mm | |

| Max. tool weight | 15.4 lbs | |

| Max. tool length | 10 inch / 12 in | |

| AVG.CHANGING TIME (ARM) |

Tool to tool | 2.7 sec. |

| Chip to chip (50% Z axis) | 6.7 sec. | |

| Air source required | 85 psi | |

| ACCURACY | Positioning | ±0.0002 in |

| Repeatability | ±0.0001 in | |

| DIMENSION | Machine weight | Approx 14,000 lbs |

| Power source required (KVA.) | 15 KVA 220v | |

| Floor space (L x W x H) | 112 x 118 x 113 in |