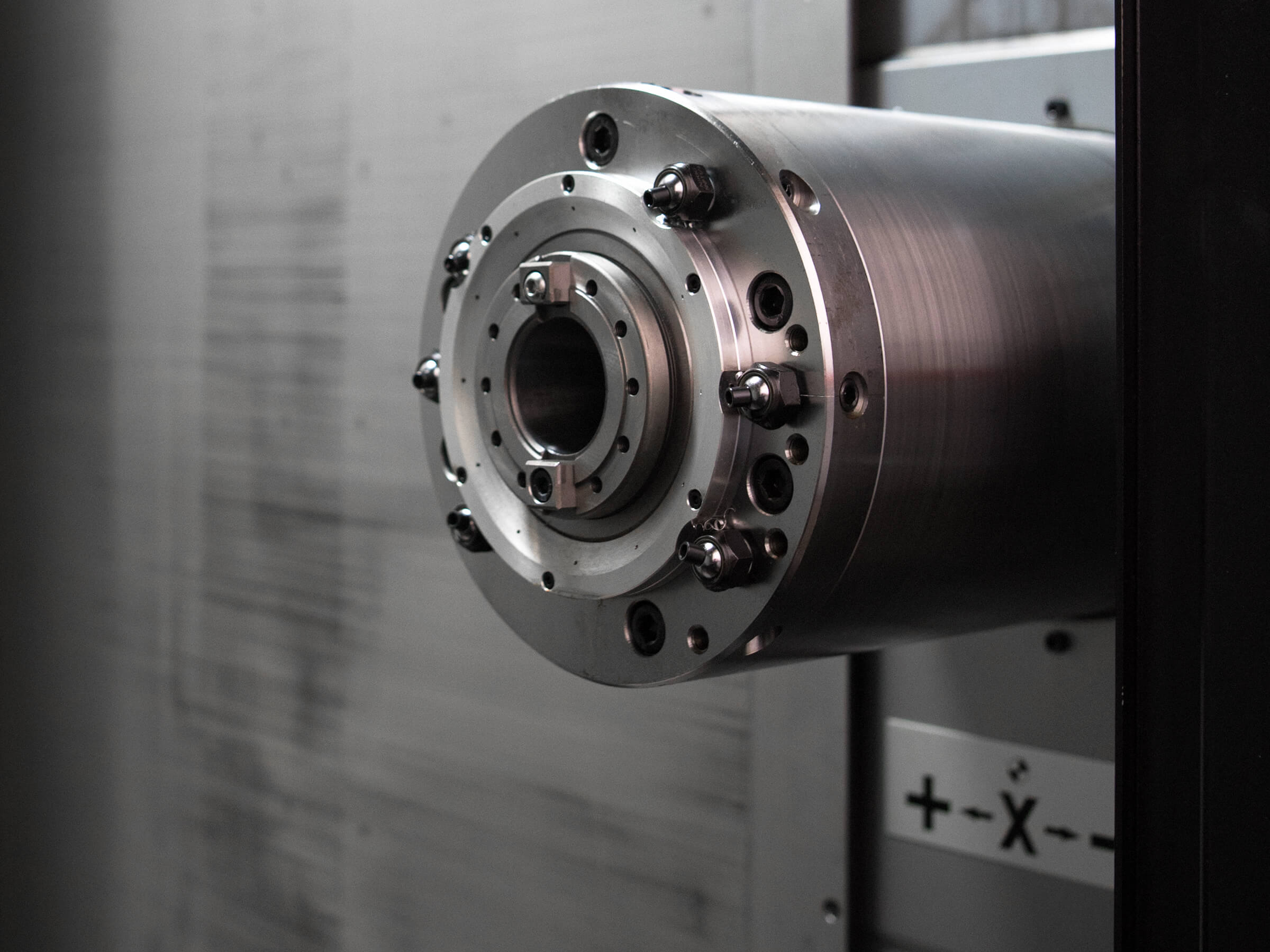

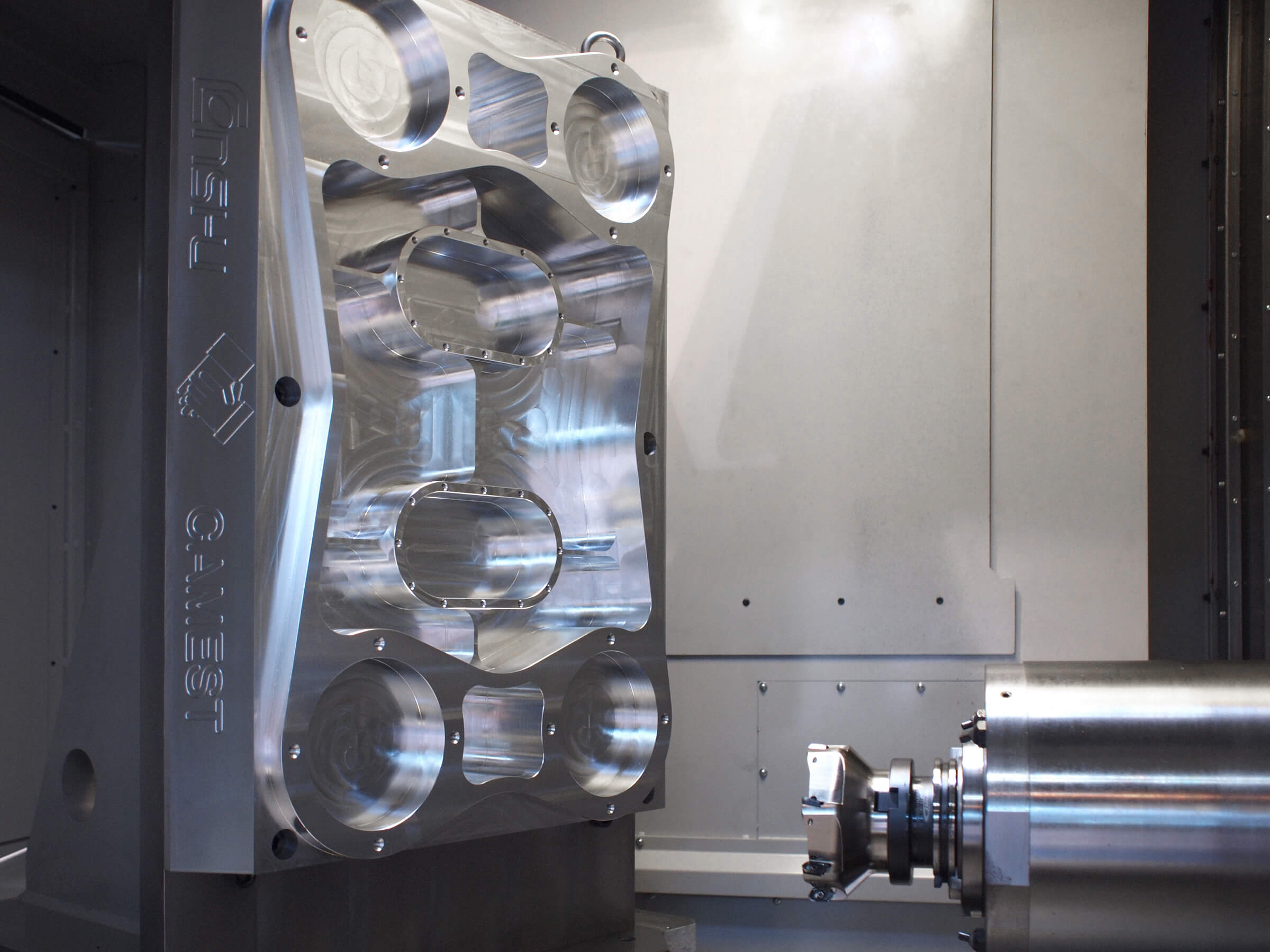

In the first place, Enshu GE Series Horizontal Machining Centers has four models. In fact, they all offer full stroke accuracy and repeatability. Due to superior design and thermal stability. Consequently, non-cutting time is reduced. In detail, through faster rapid traverse rates, axis acceleration, tool changing, and indexing. In effect, every component of these machines is engineered to ensure year after year reliable operation. Especially under the most grueling manufacturing conditions.

GE40H

Surprisingly, compact and nimble. After all, this 400mm pallet is a 40-tool capacity horizontal machining center. Explicitly ideal for secondary operations and die-cast processing. For one thing, it has a 12,000 RPM and Big Plus/CAT40 taper spindle. Obviously, this HMC can take on heavy-duty jobs in a smaller footprint.

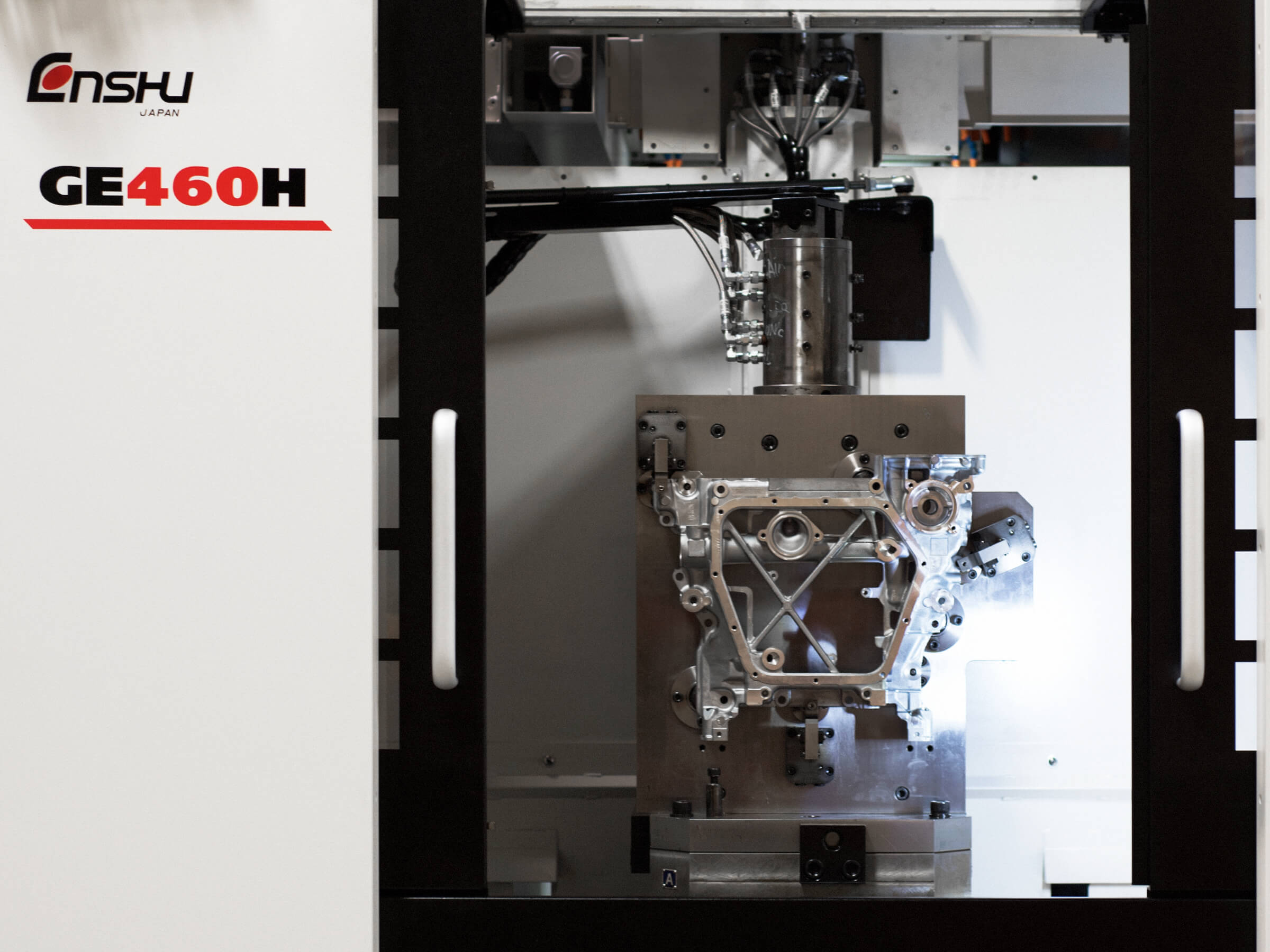

GE460H

In brief, this is an ultra-performance 40-taper horizontal machining center. Particularly features a 400mm pallet with a traveling column. That is to say, with room for additional tools and pallets. All in all, this HMC provides flexibility to expand its capabilities.

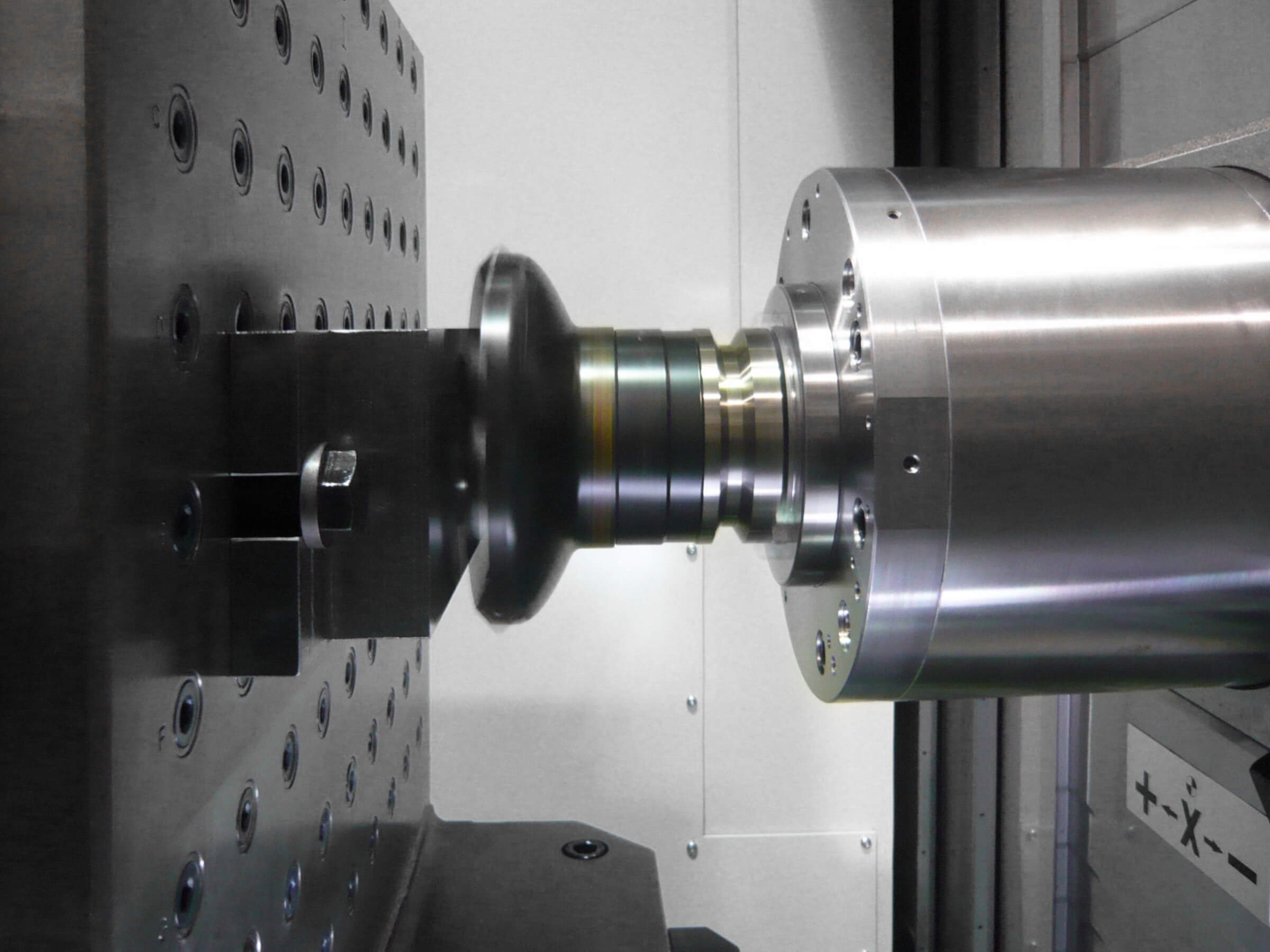

GE480H

The GE480H 40-taper horizontal machining center delivers ultra-performance. Specifically due to its large travels, high speeds, and heavy cutting spindle. Moreover, with a 500mm pallet. Therefore the HMC continues to impress with its thermal stability and reliability. Additionally, it allows for multiple configurations for the greatest machining flexibility.

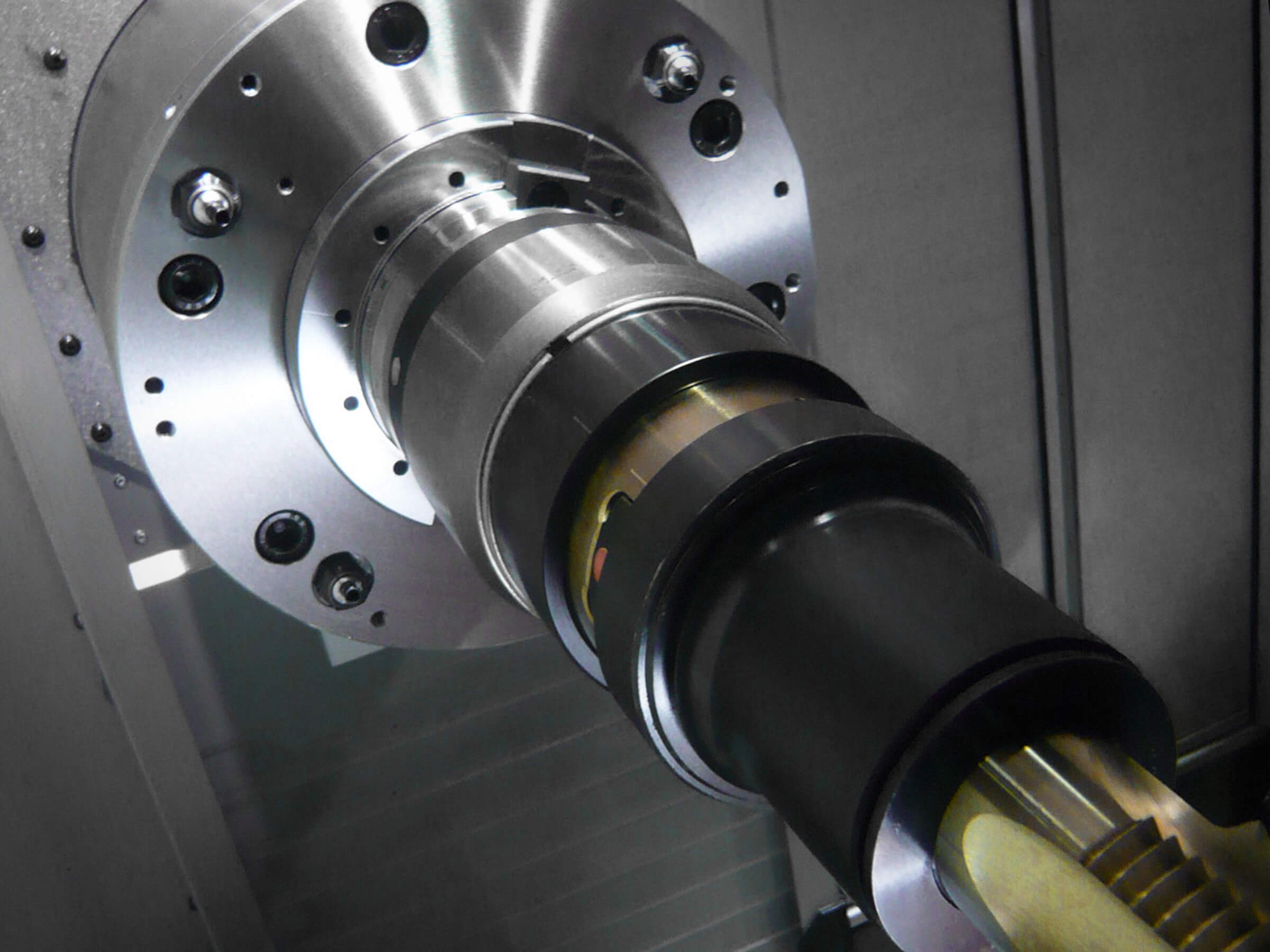

GE580H

In this case, the oversized 50-taper spindle of this horizontal machining center provides high metal removal rates in steel and aluminum. To point out comes with a 500mm pallet and 10,000RPM 54HP spindle. Indeed, the GE580H promises exceptional cutting performance and thermal stability.

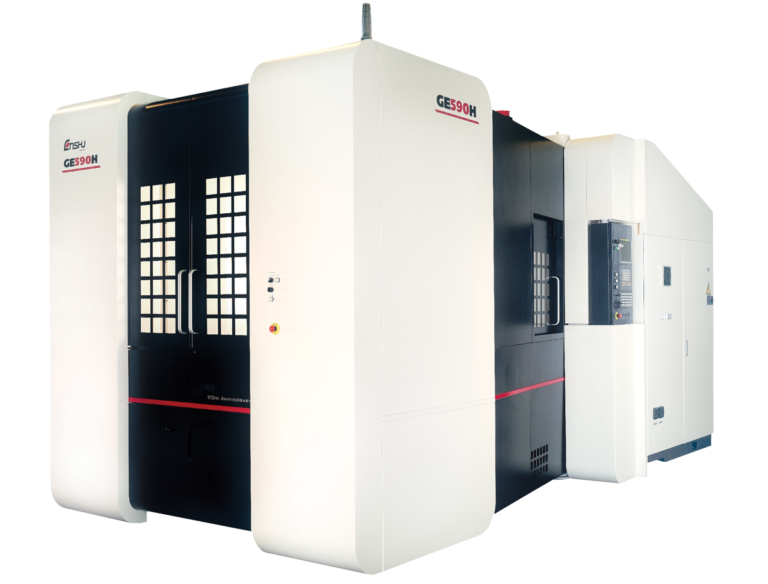

GE590H

For instance, in this 630mm 50-taper horizontal machining center. Therefore, the GE590H is guaranteed to impress. With this in mind, the rugged design of this HMC offers outstanding cutting performance with superior reliability. Especially, a full range of ATC capacities and pallet system choices for the utmost flexibility.

Ready to find out more?

Contact us today! Contact Us